Following the success of the rudder mould. I thought I'ld have a crack at a making some spreader moulds as well. These are made from some 15mm thick HPDE I had laying around. The idea is the perform a closed moulding with an inflatable bladder (long party balloon) with carbon fibre and epoxy. It appears some RC airplane DIY builds have success with this method for fuselages.

This is a simple sign for a friends business to hang on their wall.

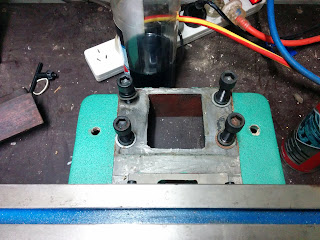

The machine is now cutting 6mm thick aluminium plate in 0.5mm DOC, 24k RPM at 1200 mm/min with a 1/8" single flute solid carbide cutter.

The parts below are to upgrade the Y & Z axis of the router to accommodate HIWIN linear rails and bearings. The brackets and Z-axis beam will also be a lot stiffer than the existing 20mm thick aluminium plate.

The goal here is to improve machine rigidity to allow larger depths of cuts for faster production times.