Fitting the X-axis ball screws with bearing blocks and NEMA 23 270 oz/in steppers on each side. The aluminium covering was added as a dust cover.

Positioning the second rail parallel to the first.

First drive of the screws with the laptop.

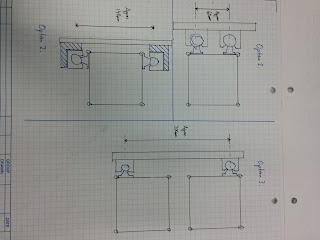

Looking at our gantry design options.

Concepts for mounting the Y-axis linear bearings. Getting the bearings as far apart as possible will help with machine rigidity.

Our 300w Ryobi trimming router with 1/4" collet that we had laying around. This was used prior to upgrading.

No comments:

Post a Comment